As global utilities and EPC contractors face increasing pressure to improve network safety, reduce losses, and accelerate electrification projects, ABC cable (Aerial Bundled Cable) has become a preferred solution for modern overhead distribution systems.

This technical guide explains what ABC cable is, how it works, and why utilities and infrastructure developers increasingly choose it for reliable, long-term power distribution.

What Is ABC Cable?

ABC cable refers to an insulated overhead conductor system where multiple aluminum phase conductors and a neutral messenger are bundled together into a single compact assembly.

Unlike traditional bare overhead conductors such as AAC, AAAC, or ACSR, ABC cable uses cross-linked polyethylene (XLPE) insulated conductors, allowing the line to operate safely even in close proximity to buildings, trees, and public areas.

For power utilities, urban developers, and rural electrification programs, ABC cable offers an advanced alternative to conventional overhead lines while retaining the advantages of overhead installation.

Why ABC Cable Is Becoming the Preferred Distribution Standard

1. Improved Public and Network Safety

One of the primary drivers behind ABC cable adoption is safety. The insulated construction significantly reduces the risk of:

Accidental contact with live conductors

Short circuits caused by vegetation

Flashovers during storms and heavy wind conditions

For utilities operating in dense residential zones, informal settlements, or roadside installations, ABC cable provides a much safer overhead solution.

2. Reduced Power Loss and Fault Rate

The compact and insulated design of aerial bundled cable minimizes phase-to-phase faults and external interference. This results in:

Lower outage frequency

Improved system reliability

Reduced maintenance intervention

For grid operators, this translates into measurable operational savings over the lifecycle of the line.

3. Strong Protection Against Electricity Theft

In many developing and fast-growing power networks, illegal connections are a major concern. ABC cable offers higher resistance to tampering and unauthorized tapping, helping utilities protect revenue and improve network discipline.

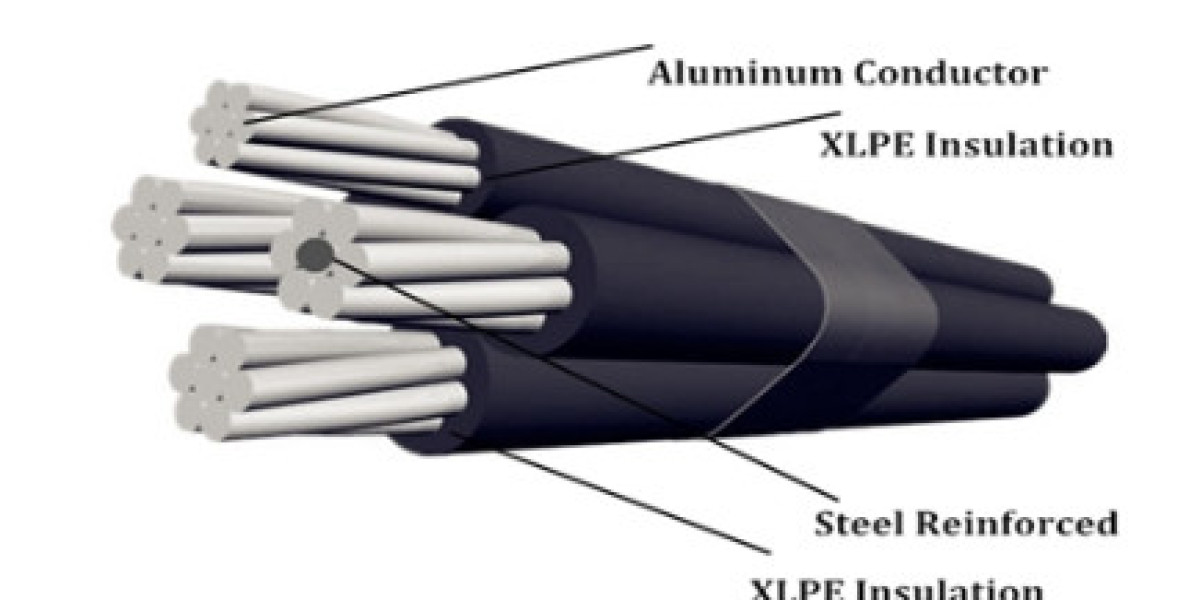

Typical Structure of ABC Cable

An engineered ABC cable system generally consists of:

Phase Conductors

Made from stranded aluminum conductors (commonly aluminum alloy or pure aluminum), each phase is insulated with XLPE.

Neutral Messenger / Supporting Conductor

The neutral conductor often acts as the mechanical support for the bundled assembly and carries both mechanical tension and electrical return current.

Optional Street-Lighting or Control Cores

Some ABC cable configurations include additional insulated conductors for public lighting or control circuits.

This flexible structure allows ABC cable to be customized for different voltage levels and network layouts.

Standard Applications of ABC Cable

ABC cable is widely used in:

Low-voltage overhead distribution networks

Urban and suburban power distribution projects

Rural electrification programs

Industrial park and commercial zone infrastructure

Service drop connections to buildings

For utilities seeking safer alternatives to bare overhead conductors without moving to costly underground cabling, ABC cable provides an optimal middle solution.

ABC Cable vs Traditional Overhead Conductors

| Feature | ABC Cable | AAC / AAAC / ACSR |

|---|---|---|

| Insulation | Fully insulated | Bare conductor |

| Safety level | Very high | Moderate |

| Fault resistance | Excellent | Limited |

| Installation | Overhead, compact | Overhead, wider spacing |

| Theft protection | Strong | Low |

| Maintenance | Low | Moderate to high |

While AAC, AAAC, and ACSR remain critical for transmission and long-span distribution lines, ABC cable is specifically engineered for distribution environments where safety, compactness, and reliability are essential.

Key Technical Advantages for Utilities and EPC Contractors

Compact Line Design

Because the conductors are bundled together, ABC cable requires less right-of-way and narrower pole corridors. This is particularly beneficial in congested urban infrastructure projects.

Faster Installation

ABC cable systems simplify stringing operations and reduce cross-arm complexity. For EPC contractors managing large distribution rollouts, this leads to shorter construction schedules and lower installation labor costs.

Higher Network Resilience

The insulated conductors significantly reduce outages caused by wind-driven contacts, falling branches, and temporary obstructions.

ABC Cable Manufacturing Capability at HNBF Power

As a global manufacturer of overhead conductors and power cables, HNBF Power supplies high-performance ABC cable systems designed to meet the real-world demands of modern distribution networks.

HNBF Power’s ABC cable solutions are engineered with:

High-purity aluminum and aluminum alloy conductors

Durable XLPE insulation for long service life

Configurations suitable for multiple low-voltage and distribution voltage classes

Customized core arrangements for utility-specific network requirements

With deep expertise in AAC, AAAC, ACSR, ABC, LV power cable, and concentric cable manufacturing, HNBF Power supports utilities, EPC contractors, and grid developers with technically optimized and project-ready cable solutions.

Selection Considerations When Specifying ABC Cable

When engineers and procurement teams prepare an ABC cable specification, the following technical factors should be evaluated:

Conductor Size and Current Rating

Correct cross-section selection is critical to match load growth and thermal performance requirements.

Neutral Messenger Strength

The mechanical strength of the supporting conductor must meet span length and climatic load requirements.

Insulation Material and Thickness

XLPE insulation grade directly affects voltage rating, aging performance, and environmental durability.

Installation Environment

Urban density, vegetation exposure, pollution level, and coastal conditions all influence cable design choices.

A professional manufacturer with strong engineering support is essential for correct system selection.

FAQs About ABC Cable

1. What does ABC cable stand for?

ABC cable stands for Aerial Bundled Cable, a type of insulated overhead distribution cable system.

2. Is ABC cable suitable for low-voltage networks?

Yes. ABC cable is widely used in low-voltage and secondary distribution networks, especially for residential and commercial supply.

3. Can ABC cable replace bare conductors completely?

ABC cable is ideal for distribution environments, but long-distance transmission lines still typically require AAC, AAAC, or ACSR conductors.

4. Does ABC cable reduce maintenance costs?

Yes. The insulated and compact design significantly reduces fault incidents and vegetation-related maintenance.

Power Your Distribution Projects with HNBF Power

If your upcoming distribution project requires safer, more compact, and highly reliable ABC cable systems, HNBF Power is ready to support your engineering and procurement teams with customized manufacturing solutions.

Contact HNBF Power today to discuss your ABC cable specifications and receive a tailored solution designed for your power distribution network.