Why Precision Equipment Loses Stability Without the Right RU Cross Roller Bearing

Precision machinery is designed to deliver accuracy, rigidity, and smooth motion—but when instability, vibration, or positioning errors appear, productivity quickly suffers. In many cases, the problem is not the control system or structure, but the bearing at the core of the rotation. Standard bearings often struggle to handle combined loads while maintaining accuracy, leading to deformation and performance loss.

This is where an RU cross roller bearing becomes critical. Without the right bearing structure, even high-end equipment can experience reduced precision and costly downtime.

The Hidden Risks of Using Conventional Bearings in High-Load Systems

Traditional bearing designs often require separate housings or additional components to manage axial, radial, and moment loads. This increases assembly complexity and introduces alignment errors.

Common problems caused by unsuitable bearings include:

Loss of positioning accuracy

Increased vibration and noise

Structural deformation under moment loads

Shortened service life

In applications such as robotics, rotary tables, and machine tools, these issues directly impact reliability and output quality.

What Makes RU Cross Roller Bearings Different

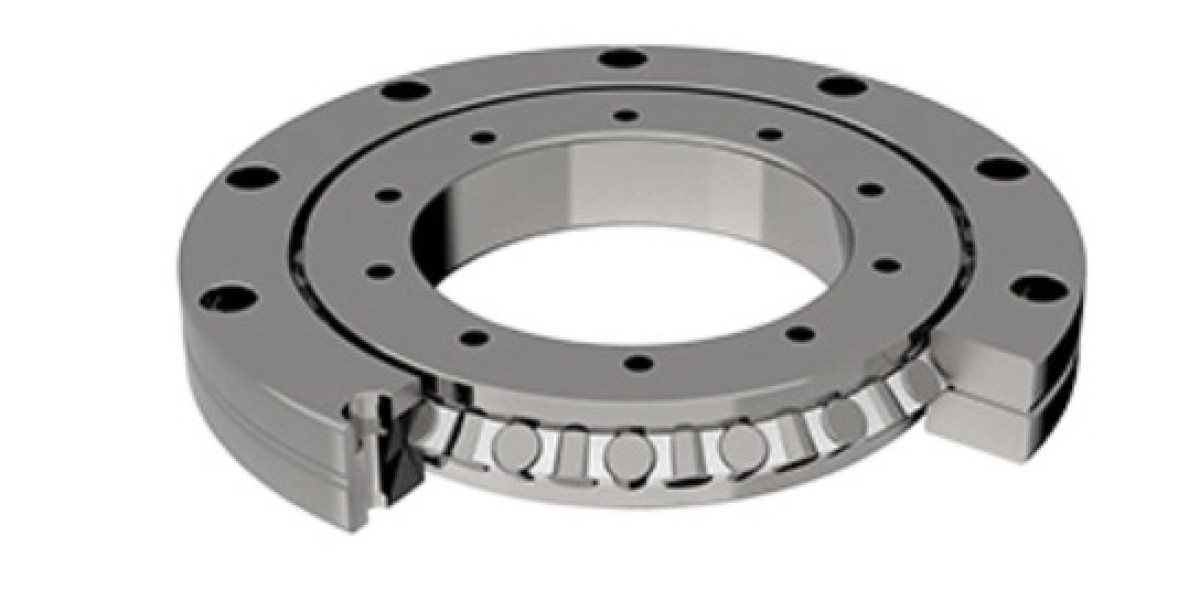

A RU cross roller bearing features an integrated inner and outer ring design with cylindrical rollers arranged orthogonally. This structure allows the bearing to handle radial, axial, and moment loads simultaneously while maintaining exceptional rigidity.

Key performance advantages include:

High load-carrying capacity in all directions

Compact design with simplified installation

Excellent rotational accuracy

Minimal elastic deformation

By integrating the bearing rings into a single unit, RU cross roller bearings eliminate the need for complex bearing housings, improving overall system stability.

Precision Manufacturing That Protects Accuracy

The performance of an RU cross roller bearing depends heavily on manufacturing precision. Tight dimensional tolerances, smooth raceway finishes, and consistent heat treatment are essential to achieving long-term reliability.

A high-quality RU cross roller bearing is produced using advanced grinding and inspection technologies to ensure:

Uniform load distribution

Reduced friction and wear

Stable operation under continuous motion

Consistent accuracy over extended service life

This level of precision is especially important in applications where even minor deviations can compromise system performance.

Reducing Downtime in Precision Motion Applications

Unplanned downtime is one of the most expensive challenges in modern manufacturing. Bearing failure often requires not only replacement but also system recalibration, increasing repair time and labor costs.

RU cross roller bearings help reduce downtime by offering:

Longer maintenance intervals

Improved resistance to fatigue

Stable performance under high moment loads

Reduced risk of sudden failure

By improving bearing durability and rigidity, manufacturers can maintain consistent operation and avoid costly production interruptions.

Where RU Cross Roller Bearings Deliver Maximum Value

Because of their compact, rigid structure, RU cross roller bearings are widely used in applications that demand precision and load stability, including:

Industrial robots and robot joints

Rotary tables and indexing systems

Machine tool spindles

Semiconductor and inspection equipment

In these environments, bearing performance directly affects positioning accuracy, repeatability, and overall system reliability.

Why the Right Bearing Choice Protects Long-Term Productivity

Selecting the correct RU cross roller bearing is not just about meeting technical specifications—it’s about ensuring stable performance, protecting equipment investment, and reducing operational risk. High-rigidity bearings support smooth motion, maintain alignment, and deliver consistent accuracy under demanding conditions.

By choosing a precision-engineered RU cross roller bearing, manufacturers can improve system reliability, reduce downtime, and maintain high performance in precision motion applications.