The Global Robotic Palletizers and De-palletizers Market is a cornerstone of the industrial automation sector, providing the critical bridge between production lines and global distribution networks. These systems use advanced robotics to automate the stacking (palletizing) and unstacking (de-palletizing) of goods, replacing one of the most physically demanding and repetitive tasks in the supply chain.

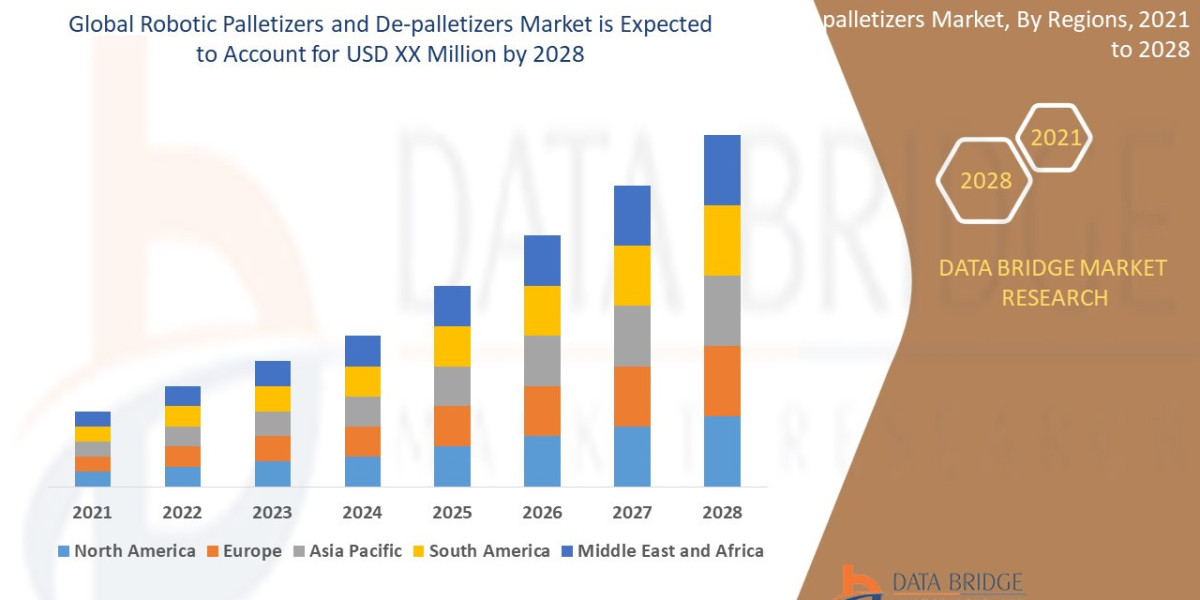

The robotic palletizers and de-palletizers market is expected to witness market growth at a rate of 4.45% in the forecast period of 2021 to 2028.

Market Size and Strategic Growth

As of 2025, the market is valued at approximately USD 2.37 billion to USD 3.1 billion, depending on the inclusion of peripheral software and service components. It is projected to experience a robust Compound Annual Growth Rate (CAGR) of 5.5% to 10.7% through 2035. This sustained growth is fueled by the transition from traditional mechanical palletizers to flexible, high-speed robotic systems that can handle a diverse array of product types with minimal changeover time.

Core Market Drivers

The shift toward robotic palletizing and de-palletizing is driven by several systemic changes in global commerce:

Labor Scarcity and Workplace Safety: Persistent labor shortages in the logistics and manufacturing sectors have made automation a necessity rather than an elective upgrade. Furthermore, palletizing is a high-risk activity for musculoskeletal injuries; robots eliminate this ergonomic hazard, reducing insurance costs and downtime.

The E-commerce Surge: The explosion of online retail has increased the demand for "mixed-SKU" palletizing—the ability to build a single pallet with different types of products. Unlike traditional machines, robotic systems equipped with 3D vision and AI can identify and stack varying box sizes and weights in real-time.

Industry 4.0 Integration: Modern IPGs (Implantable Pulse Generators) and robots are now integrated with Warehouse Management Systems (WMS). This connectivity allows for real-time data tracking, predictive maintenance, and seamless adjustment to production fluctuations.

Miniaturization and Space Constraints: Modern "cobots" (collaborative robots) feature a smaller footprint and can work alongside humans without safety cages, allowing smaller facilities to automate without expanding their physical footprint.

https://www.databridgemarketresearch.com/reports/global-robotic-palletizers-and-de-palletizers-market

Segmentation: Technology and Application

The market is highly diversified to meet the specific needs of different industries:

By Robot Type:

Articulated Robots (Dominant Share): These multi-axis arms are the most common due to their high reach, payload capacity, and extreme flexibility.

Collaborative Robots (Cobots - Fastest Growing): Designed for safety and ease of programming, cobots are rapidly gaining ground in smaller manufacturing plants and mixed-human environments.

SCARA and Delta Robots: Used for high-speed, lightweight palletizing, common in the electronics and pharmaceutical sectors.

By End-Use Industry:

Food and Beverage (Largest Segment): High volumes and strict hygiene requirements make robotics ideal for handling cases of bottled water, canned goods, and frozen foods.

Pharmaceuticals: Requires extreme precision and "no-touch" handling to prevent contamination and ensure batch integrity.

Logistics and E-commerce: The primary frontier for de-palletizing technology, where robots must unload incoming shipments of varying configurations for sortation.

Regional Insights

Asia-Pacific (Market Leader): Accounting for roughly 35-44% of the global share, this region is driven by China's aggressive industrial modernization and the massive manufacturing bases in Japan and South Korea.

North America: A mature market focused on the integration of AI and high-speed fulfillment centers to support the world's largest e-commerce economy.

Europe: Driven by strict labor laws and a high emphasis on energy-efficient and sustainable automation solutions.

Browse More Reports:

Global Casting and Splinting Market

Global Muckle Wells Syndrome Market

Global Capacitor Bank Controllers Substation Automation Market

Global Metallic Pigments Market

Global Primary Biliary Cirrhosis Market

Global High Purity Specialty Gases Market

Global Merkel Cell Carcinoma Treatment Market

Global Speech Recognition AI (Artificial Intelligence) Camera Market

Global Hosted Telephone Systems Market

Global Fetal and Neonatal Critical Care Equipment Market

North America Busbar Market

Global Carcinoembryonic Antigen (CEA) Market

Global Events Services Market

Global Soda Water Dispenser Market

Global Diesel Bottled (Aftermarket) Fuel Additives Market

Conclusion

The Global Robotic Palletizers and De-palletizers Market is moving beyond simple mechanical repetition into a new era of intelligent adaptability. The future of the market lies in "blind" de-palletizing, where AI-driven vision systems allow robots to unload unknown cargo with the same dexterity as a human. As payload capacities increase and the cost of collaborative technology decreases, robotic palletizing will become standard even for small-to-medium enterprises (SMEs). Ultimately, these systems are no longer just tools for efficiency; they are the essential infrastructure required to keep pace with the speed and complexity of 21st-century global trade.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com