Conveyor and V-belt systems are crucial for material handling and transportation in various industries. The demand for these systems is rising due to the growing need for efficient logistics and supply chain management. As companies invest in automation and advanced material handling solutions, the market for conveyor and V-belt systems is expected to expand significantly, driven by innovations that enhance efficiency and reduce operational costs.

The power transmission belting market plays a critical role in industrial operations, as belts are essential for transmitting mechanical power between rotating shafts in machinery. These belts are used across a wide range of sectors, including automotive, manufacturing, agriculture, and mining. As automation and mechanization continue to grow globally, the demand for reliable and efficient power transmission systems is increasing. Power transmission belts offer a cost-effective and efficient solution, making them an integral component of modern industrial processes.

Market Dynamics and Key Drivers

The rising demand for energy-efficient systems, coupled with growing industrial automation, is driving market growth. The adoption of advanced materials, such as synthetic rubber, polyurethane, and composite materials, has enhanced the performance and lifespan of belts. Moreover, industries are increasingly seeking solutions that reduce maintenance costs and energy loss. The growing use of power transmission belts in automotive engines, conveyors, and heavy machinery is further contributing to the market’s expansion.

Technological Developments

Innovation in materials and manufacturing processes has led to the development of lightweight, high-strength, and temperature-resistant belts. Advanced vulcanization techniques and precision engineering have improved product performance and reduced wear and tear. Furthermore, the integration of smart sensors for monitoring belt tension and operational efficiency is becoming a new trend. These technological upgrades are helping industries minimize downtime and improve productivity, thus fueling demand for high-performance belts.

Challenges and Market Constraints

Despite positive growth trends, the power transmission belting market faces challenges such as fluctuating raw material prices and competition from direct drive systems. Environmental concerns related to rubber production also impact market dynamics. However, increasing focus on sustainable materials and circular economy practices is expected to mitigate these challenges. Manufacturers are also emphasizing recyclable and biodegradable belt materials to align with global environmental standards.

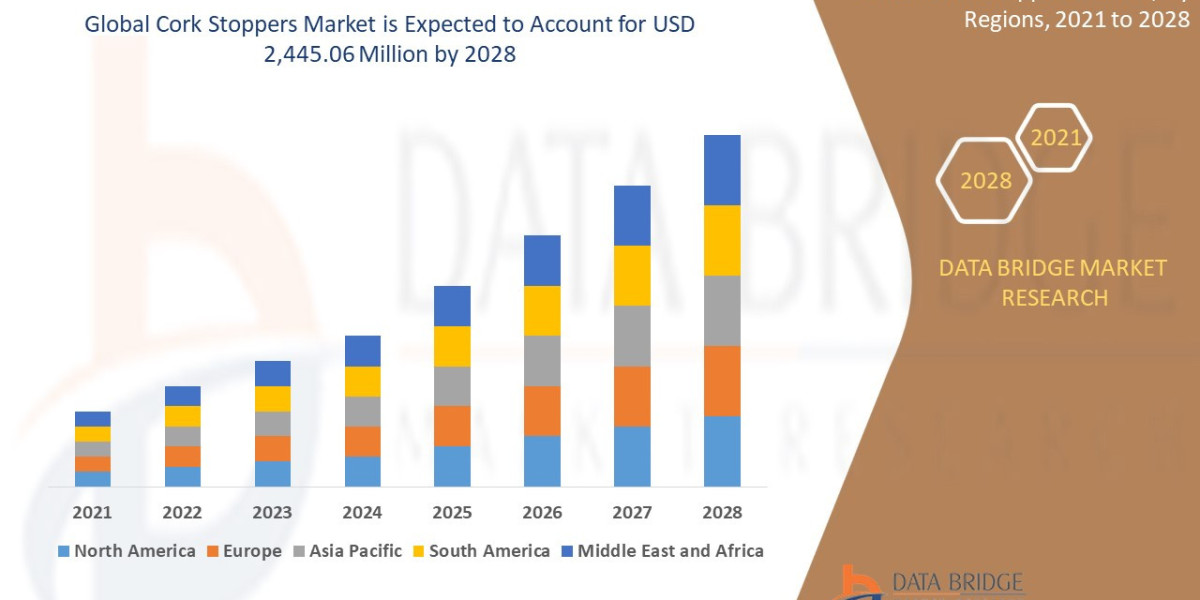

Regional Insights

The Asia-Pacific region dominates the global power transmission belting market due to rapid industrial growth in countries such as China, India, and Japan. North America and Europe also hold significant market shares, driven by strong manufacturing and automotive sectors. The Middle East, Africa, and Latin America are emerging markets, showing potential growth due to expanding industrial bases and agricultural modernization.

Competitive Landscape

Major players in the market are focusing on R&D to introduce high-performance belts with improved efficiency and reduced operational costs. Companies are also engaging in partnerships and acquisitions to expand their product portfolios and geographic presence. With increasing industrial automation, the demand for belts capable of operating under extreme conditions is expected to rise, pushing manufacturers toward continuous innovation.

Future Outlook

The future of the power transmission belting market looks promising as industries increasingly adopt automation and energy-efficient systems. The transition toward sustainable materials, coupled with advancements in smart monitoring technologies, will further shape market growth. As global industries move toward higher productivity and reduced carbon emissions, power transmission belts will remain indispensable components of mechanical operations.

FAQs

Q1. What is the purpose of power transmission belts?

They are used to transmit mechanical power between rotating machinery components.

Q2. Which industries use power transmission belts most?

They are widely used in automotive, industrial, and agricultural sectors.

Q3. What are the latest trends in the market?

Sustainability, smart monitoring, and advanced materials are key trends.

More Related Reports: