Dosing Pump Market - The Dosing Pump Market focuses on precision fluid handling systems designed for controlled chemical and liquid injection across industries such as water treatment, oil & gas, and pharmaceuticals.

The Dosing Pump Market constitutes the specialized industrial segment dedicated to the manufacture, distribution, and maintenance of pumps designed for the precise, controlled injection of chemicals or fluids into a process stream. This market is fundamentally driven by the need for accuracy and reliability in processes where the quantity of added substance is critical to the final outcome, safety, or compliance with regulatory standards. Its stability is anchored by the continuous demand from essential infrastructure and manufacturing sectors globally.

One of the principal demand engines for this market is the water and wastewater treatment sector. In municipal facilities, dosing pumps are indispensable for chemical coagulation, flocculation, disinfection with chlorine or hypochlorite, and meticulously adjusting the water's pH balance. The sheer volume of water processed globally and the universal, non-negotiable requirement for clean water necessitate a constant and growing deployment of high-performance dosing systems. Industrial wastewater, with its complex mixture of contaminants, also demands sophisticated dosing solutions for neutralization and specialized chemical breakdown, thereby fueling a steady replacement and expansion cycle within the market.

Another significant area of application lies in the chemical and petrochemical industries. Here, dosing pumps are not merely auxiliary equipment; they are integral components of reaction control. They are used for the precise injection of catalysts, inhibitors, or additives to manage polymerization processes, prevent corrosion in pipelines, or ensure product quality. The highly corrosive or hazardous nature of many of these chemicals mandates pumps constructed from specialized, resistant materials, driving demand for high-end, durable product lines. The requirements of these industries push the boundaries of pump material science and sealing technology.

The market is also shaped by the growing sophistication of the pharmaceutical and food and beverage sectors. In these regulated environments, the purity and consistency of the end product depend heavily on precise ingredient addition. Dosing pumps are used for metering active pharmaceutical ingredients, flavorings, preservatives, and cleaning agents. The stringent hygienic standards of these industries necessitate pumps with specific design features, such as smooth internal surfaces and quick-release connections for sterilization, driving a specialized, premium sub-segment of the market focused on sanitary design and validation.

The competitive landscape of the Dosing Pump Market is diverse, ranging from large, multinational industrial pump manufacturers offering comprehensive fluid management solutions to smaller, specialized companies focusing solely on high-precision or unique dosing technologies. Competition centers on three key factors: accuracy and turndown ratio, which is the ability to maintain precision across a wide range of flow rates; reliability and material compatibility, ensuring long service life when handling aggressive chemicals; and integration capability, allowing the pumps to seamlessly connect with modern industrial control systems and remote monitoring platforms.

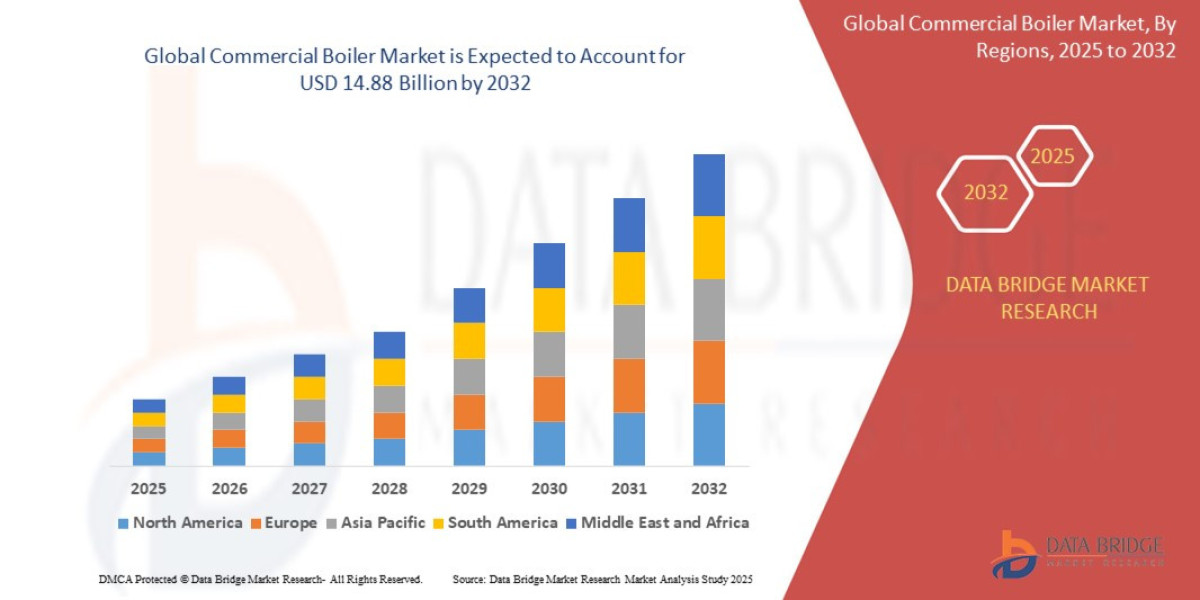

Geographically, market growth is often correlated with rapid industrialization and increasing environmental regulation. Regions undergoing significant infrastructure modernization, particularly in the development of new centralized water treatment facilities or the expansion of chemical manufacturing capacity, exhibit the strongest demand for new installations. Furthermore, the mature markets of industrialized regions drive consistent revenue through the replacement of aging assets and the upgrade to smart, digitally integrated dosing technology. Overall, the market's trajectory is one of stable expansion, underpinned by essential global processes and the continuous pursuit of greater operational control and environmental compliance.

Frequently Asked Questions (FAQ)

Q1: What fundamental need does the Dosing Pump Market serve in process industries?A: The market serves the fundamental requirement for accurate and reliable introduction of a specific quantity of fluid or chemical into a main process stream to control reaction rates, ensure product quality, or maintain regulatory compliance.

Q2: How does regulatory pressure affect the demand for dosing pump technology?A: Increasing regulatory pressure, particularly concerning water quality and environmental discharge standards, compels industries to upgrade their chemical treatment processes, driving continuous demand for more precise and controllable dosing equipment.

Q3: What role does material science play in the design of high-end dosing pumps?A: Material science is crucial as high-end pumps must be constructed from chemically inert and robust materials to ensure long-term reliability and integrity when handling a diverse array of corrosive, viscous, or otherwise aggressive processing fluids.

More Related Reports: