"Executive Summary Asia-Pacific Foundry Chemicals Market Size and Share: Global Industry Snapshot

CAGR Value

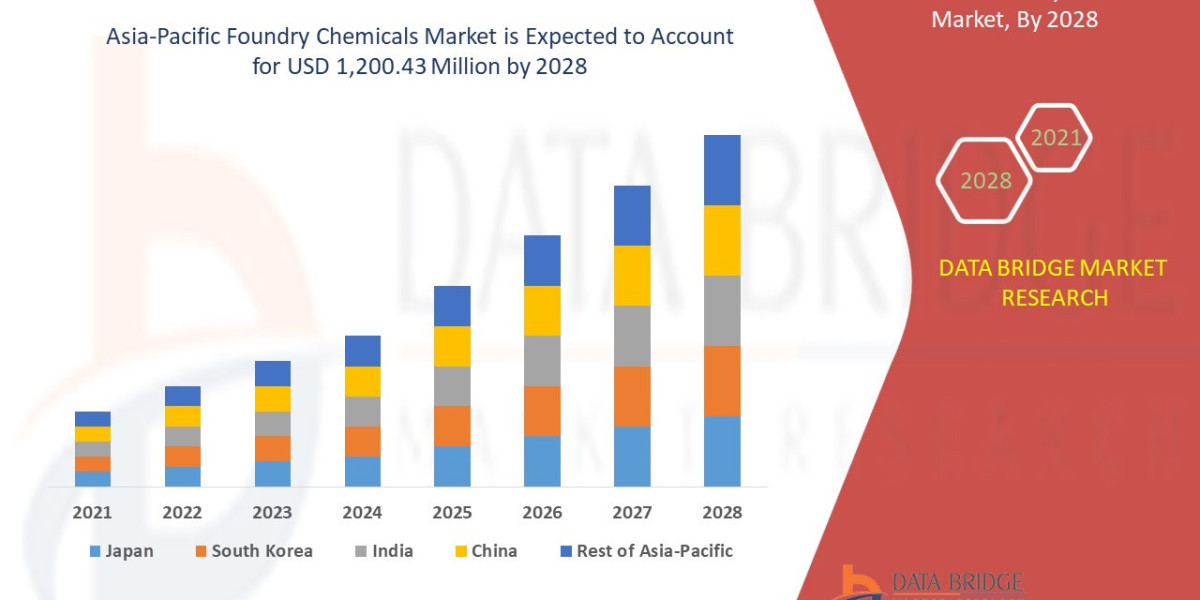

The foundry chemicals market is expected to gain market growth in the forecast period of 2021 to 2028. Data Bridge Market Research analyses that the market is growing at a CAGR of 5.1% in the forecast period of 2021 to 2028 and is expected to reach USD 1,200.43 million by 2028. The increasing demand for metal casting in the automotive market is acting as a driver for the foundry chemicals market in the forecast period.

Asia-Pacific Foundry Chemicals Market report offers the most appropriate solution for the business requirements in many ways. To be successful in this competitive age, it is very imperative to get well-versed about the major happenings in the Asia-Pacific Foundry Chemicals Market industry which is possible only with the excellent market report like this one. To make aware about the industry insights so that business never misses anything, this is the valuable market report. The report also analyzes the market status, market share, growth rate, sales volume, future trends, market drivers, market restraints, revenue generation, opportunities and challenges, risks and entry barriers, sales channels, and distributors. A large scale Asia-Pacific Foundry Chemicals Market report not only assists with the informed decision making but also helps with smart working.

The top notch Asia-Pacific Foundry Chemicals Market report defines various segments related to Asia-Pacific Foundry Chemicals Market industry and market with thorough research and analysis. These can be listed as; industry outlook, critical success factors (CSFs), industry dynamics, market drivers, market restraints, market segmentation, value chain analysis, key opportunities, application and technology outlook, regional or geographical insight, country-level analysis, key company profiles, competitive landscape, and company market share analysis. So, business can surely go with an all-embracing Asia-Pacific Foundry Chemicals Market research report to take business to the highest level of growth and success.

Stay informed with our latest Asia-Pacific Foundry Chemicals Market research covering strategies, innovations, and forecasts. Download full report: https://www.databridgemarketresearch.com/reports/asia-pacific-foundry-chemicals-market

Asia-Pacific Foundry Chemicals Market Trends & Analysis

Segments

- By Type: Binders, Fluxes, Alloys, Parting Agents, Sands, Others

- By Application: Iron, Steel, Aluminum, Others

- By Country: China, Japan, India, South Korea, Australia, Rest of Asia-Pacific

The Asia-Pacific foundry chemicals market is segmented based on type, application, and country. In terms of type, the market is categorized into binders, fluxes, alloys, parting agents, sands, and others. Binders are substances that hold the sand particles together; fluxes are used to promote fusion or melting; alloys are a mixture of two or more elements; parting agents are used to prevent sand from sticking to the mold; sands are primary materials in foundry casting. Based on application, the market is divided into iron, steel, aluminum, and others. Geographically, the market is analyzed across key countries such as China, Japan, India, South Korea, Australia, and the rest of Asia-Pacific.

Market Players

- ASK Chemicals

- Imerys

- HA International LLC

- Vesuvius

- Elkem AS

- Foseco

- HA-International

The Asia-Pacific foundry chemicals market is highly competitive with the presence of several key players. Some of the prominent market players operating in this region include ASK Chemicals, Imerys, HA International LLC, Vesuvius, Elkem AS, Foseco, and HA-International. These companies are focusing on strategic initiatives such as mergers, acquisitions, partnerships, and new product launches to strengthen their market position and expand their customer base.

One key insight into the Asia-Pacific foundry chemicals market is the increasing focus on sustainability and environmental regulations. With growing concerns regarding the environmental impact of industrial processes, foundry operations are under scrutiny to adopt more sustainable practices. Market players are investing in research and development to develop eco-friendly foundry chemicals that minimize emissions and waste generation. This shift towards sustainability is driven by stringent regulations imposed by governments to reduce carbon footprint and promote green manufacturing practices. Companies that can offer innovative, sustainable solutions are likely to gain a competitive edge in the market and attract environmentally-conscious customers.

Another significant trend in the Asia-Pacific foundry chemicals market is the growing demand for high-performance foundry chemicals to enhance operational efficiency. Foundries are continuously seeking ways to improve productivity, reduce defects, and optimize production processes. This has led to a rising demand for advanced binders, fluxes, and alloys that can improve casting quality and yield. Market players are investing in developing high-performance foundry chemicals that offer superior thermal stability, better sand consolidation, and improved metal flow control. By providing solutions that help foundries achieve higher efficiency and cost-effectiveness, companies can capitalize on the increasing demand for quality products in the market.

Additionally, digitalization and technology integration are reshaping the Asia-Pacific foundry chemicals market landscape. Industry 4.0 technologies such as automation, Internet of Things (IoT), and data analytics are revolutionizing foundry operations, making them more efficient and data-driven. Market players are adopting digital solutions to monitor and optimize key processes, predict maintenance needs, and ensure consistent product quality. By embracing digital transformation, foundry chemical manufacturers can streamline operations, reduce downtime, and offer customized solutions to meet the specific needs of different applications and industries. This digital shift is expected to drive innovation and competitiveness within the market as companies leverage technology to stay ahead of the curve.

In conclusion, the Asia-Pacific foundry chemicals market is witnessing significant developments driven by sustainability initiatives, demand for high-performance products, and digital transformation. Market players need to stay abreast of these trends and adapt their strategies to cater to the evolving needs of the industry. By focusing on innovation, sustainability, and technology integration, companies can position themselves for success in the dynamic and competitive foundry chemicals market in the Asia-Pacific region.The Asia-Pacific foundry chemicals market is experiencing notable trends and developments that are shaping the industry landscape. One key aspect is the increasing emphasis on sustainability and environmental regulations. With a growing awareness of the environmental impact of industrial processes, foundry operations are under pressure to adopt more eco-friendly practices. Market players are investing in research and development to create sustainable foundry chemicals that reduce emissions and waste generation. This shift towards sustainability is largely driven by stringent government regulations aimed at minimizing carbon footprint and promoting green manufacturing practices. Companies that can offer innovative, environmentally friendly solutions are likely to gain a competitive advantage and attract customers who prioritize sustainability.

Furthermore, there is a growing demand for high-performance foundry chemicals in the Asia-Pacific market. Foundries are constantly looking for ways to enhance operational efficiency, reduce defects, and optimize production processes. This trend has led to an increased requirement for advanced binders, fluxes, and alloys that can enhance casting quality and productivity. Market players are investing in developing high-performance foundry chemicals that offer superior thermal stability, improved sand consolidation, and better metal flow control. By providing solutions that help foundries achieve higher efficiency and cost-effectiveness, companies can tap into the escalating demand for superior quality products in the market.

In addition, digitalization and technology integration are reshaping the Asia-Pacific foundry chemicals market. Industry 4.0 technologies such as automation, Internet of Things (IoT), and data analytics are revolutionizing foundry operations by making them more efficient and data-driven. Market players are incorporating digital solutions to monitor and optimize critical processes, predict maintenance requirements, and ensure consistent product quality. By embracing digital transformation, foundry chemical manufacturers can streamline operations, minimize downtime, and offer tailored solutions to meet the unique demands of various applications and industries. This shift towards digitalization is anticipated to fuel innovation and competitiveness within the market as companies leverage technology to maintain a competitive edge.

In conclusion, the Asia-Pacific foundry chemicals market is undergoing substantial transformations driven by sustainability initiatives, the demand for high-performance products, and digital advancements. Market players must remain attentive to these trends and adjust their strategies to meet the evolving needs of the industry. By prioritizing innovation, sustainability, and technological integration, companies can position themselves for success in the dynamic and competitive foundry chemicals market in the Asia-Pacific region.

Learn about the company’s position within the industry

https://www.databridgemarketresearch.com/reports/asia-pacific-foundry-chemicals-market/companies

Asia-Pacific Foundry Chemicals Market Overview: Strategic Questions for Analysis

- What does the current research say about the size of the Asia-Pacific Foundry Chemicals Market?

- What is the predicted CAGR until the end of the forecast period?

- What are the significant components of the Asia-Pacific Foundry Chemicals Market segmentation?

- Which market players hold a competitive edge?

- What innovations have taken place recently in the Asia-Pacific Foundry Chemicals Market?

- What countries form the scope of the geographical study?

- Which region holds the title of fastest-growing?

- Which country is expected to hold a leadership position?

- Where is the majority of Asia-Pacific Foundry Chemicals Market value concentrated?

- Which country’s growth outpaces others?

Browse More Reports:

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

"