Introduction

The Metal Fabrication Market refers to the global industry involved in cutting, bending, welding, machining, and assembling metal structures and components. These fabricated metal products are essential for a wide range of industries, including construction, automotive, aerospace, energy, electronics, and heavy machinery. Metal fabrication plays a critical role in transforming raw metals into functional and high-performance products that support industrial and economic development.

In recent years, the Metal Fabrication Market has experienced steady growth. Rapid urbanization, infrastructure expansion, and industrial automation have increased the demand for precision-engineered metal components. At the same time, advancements in fabrication technologies have improved efficiency, accuracy, and scalability. As global manufacturing activity continues to recover and expand, metal fabrication remains a backbone of the modern industrial ecosystem.

Stay ahead with crucial trends and expert analysis in the latest Metal Fabrication Market report. Download now: https://www.databridgemarketresearch.com/reports/global-metal-fabrication-market

Market Overview

The Metal Fabrication Market has evolved significantly over time. Traditionally, fabrication relied on manual processes and basic machinery. Over the years, the adoption of automated systems, computer numerical control machines, and advanced welding technologies has reshaped the industry. These developments have improved production speed, reduced material waste, and enhanced product quality.

Historically, market growth has been closely linked to industrial output and construction activity. During periods of infrastructure development and manufacturing expansion, demand for fabricated metal products rises sharply. Looking ahead, the market is expected to witness consistent growth driven by infrastructure investments, renewable energy projects, and increasing demand for lightweight yet durable metal components.

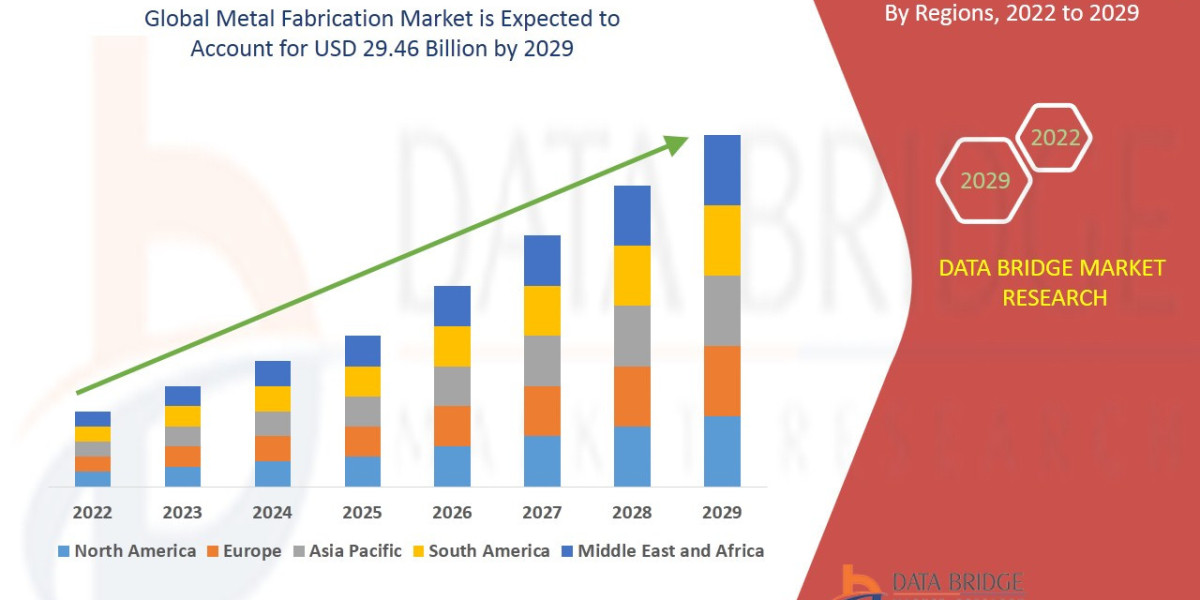

Asia-Pacific represents one of the largest and fastest-growing regions in the Metal Fabrication Market. Rapid industrialization, urban development, and strong manufacturing bases in countries such as China, India, and Southeast Asian nations support high demand. North America also holds a significant market share due to advanced manufacturing capabilities and strong demand from automotive, aerospace, and defense sectors. Europe remains an important market, supported by industrial modernization, sustainability initiatives, and a focus on high-quality engineering.

Key Market Drivers

One of the primary drivers of the Metal Fabrication Market is growth in the construction and infrastructure sector. Large-scale projects such as bridges, commercial buildings, industrial facilities, and transportation networks rely heavily on fabricated steel and aluminum components. Government investments in infrastructure development directly boost demand for metal fabrication services.

Technological advancements are another major growth factor. Automation, robotics, and digital fabrication tools have transformed traditional metalworking processes. These technologies increase productivity, improve precision, and reduce labor dependency. For example, laser cutting and automated welding systems allow fabricators to produce complex designs with high consistency and lower error rates.

The automotive and transportation industries also contribute significantly to market growth. Manufacturers increasingly use fabricated metal components to improve vehicle strength, safety, and performance. The shift toward electric vehicles has further increased demand for lightweight metal structures, battery enclosures, and specialized components.

In addition, the expansion of renewable energy projects supports metal fabrication demand. Wind turbines, solar panel mounting systems, and power transmission infrastructure require large volumes of fabricated metal parts. As countries invest in clean energy, metal fabrication companies benefit from long-term project pipelines.

Market Segmentation

The Metal Fabrication Market can be segmented by process type, metal type, end-user industry, and region. By process type, cutting, machining, welding, forming, and assembly are key segments. Among these, cutting and welding processes hold significant shares due to their widespread use across industries.

By metal type, the market includes steel, aluminum, copper, and other alloys. Steel dominates the market because of its strength, durability, and cost-effectiveness. Aluminum is gaining popularity due to its lightweight nature and corrosion resistance, especially in automotive and aerospace applications.

In terms of end-user industries, construction remains the largest segment. Fabricated metal products are essential for structural frameworks, roofing systems, and reinforcement components. The automotive industry is another major segment, driven by high-volume production and continuous design innovation. Other important end users include energy, aerospace, electronics, shipbuilding, and industrial equipment manufacturing.

Regionally, Asia-Pacific leads due to large-scale manufacturing activity and infrastructure development. North America focuses on high-precision fabrication and advanced manufacturing. Europe emphasizes quality, sustainability, and compliance with strict industrial standards.

Competitive Landscape

The Metal Fabrication Market is highly competitive and fragmented, with a mix of large multinational companies and small to medium-sized fabricators. Leading players focus on expanding production capacity, adopting advanced technologies, and offering customized solutions to meet diverse customer needs.

Product innovation plays a key role in maintaining competitiveness. Companies invest in advanced machinery, digital design tools, and automation to improve efficiency and reduce turnaround times. Many players also focus on value-added services such as design support, prototyping, and end-to-end fabrication solutions.

Strategic partnerships and acquisitions are common in the market. Larger companies acquire specialized fabricators to expand their service offerings or enter new regional markets. Collaboration with equipment manufacturers and technology providers helps fabricators stay updated with the latest production techniques.

Competition has also encouraged a stronger focus on quality, safety, and compliance. Companies that can deliver consistent quality while meeting regulatory and customer standards gain a competitive advantage in long-term contracts.

Challenges and Restraints

Despite positive growth prospects, the Metal Fabrication Market faces several challenges. Fluctuating raw material prices are a major concern. Changes in steel and aluminum prices directly impact production costs and profit margins, making cost management difficult for fabricators.

Labor shortages also pose a challenge. Skilled welders, machinists, and technicians are in high demand, yet supply remains limited in many regions. This shortage can slow production and increase labor costs.

High capital investment requirements act as another restraint. Advanced fabrication equipment and automation systems require significant upfront investment. Small and medium-sized enterprises may struggle to adopt new technologies due to financial constraints.

In addition, regulatory compliance related to workplace safety, environmental protection, and emissions can increase operational complexity. Fabricators must continuously adapt to evolving regulations, which may add to costs and administrative burdens.

Future Outlook

The future of the Metal Fabrication Market appears stable and promising. Infrastructure development, industrial expansion, and energy transition projects will continue to generate strong demand for fabricated metal products. As industries focus on efficiency and sustainability, fabricators will increasingly adopt energy-efficient machinery and waste reduction practices.

Digitalization is expected to shape the next phase of market growth. Technologies such as smart manufacturing, data analytics, and automated quality control will enhance productivity and reduce downtime. Additive manufacturing and hybrid fabrication techniques may also complement traditional metalworking processes.

Demand for customized and precision-engineered components is likely to increase. Customers seek tailored solutions that meet specific design and performance requirements. Fabricators that invest in advanced design capabilities and flexible production systems will be well positioned to capture future opportunities.

Overall, the Metal Fabrication Market is set to benefit from long-term industrial and infrastructure trends, supported by continuous technological advancement and expanding end-user applications.

Conclusion

The Metal Fabrication Market remains a vital part of the global industrial landscape. It supports construction, transportation, energy, and manufacturing sectors through the production of essential metal components. Strong demand drivers such as infrastructure investment, technological innovation, and renewable energy expansion continue to fuel market growth.

While challenges such as raw material price volatility and labor shortages persist, ongoing innovation and strategic investments are helping the industry adapt. Looking forward, the Metal Fabrication Market offers significant potential for companies that focus on efficiency, quality, and advanced manufacturing capabilities in a rapidly evolving global economy.

Frequently Asked Questions (FAQs)

What is the growth rate of the Metal Fabrication Market?

The Metal Fabrication Market is experiencing steady growth, supported by infrastructure development, industrial expansion, and rising demand from automotive and energy sectors.

Which region is expected to dominate the Metal Fabrication Market in the future?

Asia-Pacific is expected to remain a dominant region due to rapid industrialization, urban development, and strong manufacturing activity.

Who are the leading players in the Metal Fabrication Market?

The market includes a mix of global manufacturing companies and regional fabricators offering cutting, welding, machining, and assembly services.

What are the major challenges faced by the Metal Fabrication Market?

Key challenges include fluctuating raw material prices, skilled labor shortages, high capital investment needs, and regulatory compliance requirements.

What are the future opportunities in the Metal Fabrication Market?

Future opportunities include infrastructure projects, renewable energy installations, advanced automation, and demand for customized precision metal components.

Browse More Reports:

Global Universal Flash Storage Market

Global Unmanned Marine Vehicles Market

Global Urothelial Cancer Drugs Market

Global Vaccum Gas Oil Market

Global Vascular Embolization Market

Global Vehicle Cargo Box Market

Global Veterinary Infectious Disease Diagnostics Market

Global Virtual Agents Intelligent Process Automation Market

Global Virtual Mobile Infrastructure Market

Global Voice-Activated Medical Assistants Market

Global Waldenstrom’s Macroglobulinemia (WM) Treatment Market

Global Well Drilling Equipment Rental Market

Global Aftermarket Combustion Engine Repairs Market

Global Aircraft Refurbishing Market

Global Abetalipoproteinemia Treatment Market

Global Alcoholic Beverage Processing Equipment Market

Global Ambulatory Healthcare Information Technology (IT) Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com