The Automotive Steering Knuckle Market Share reflects how different manufacturers, materials, vehicle segments, and regions are performing in this growing market. Understanding market share is crucial for businesses and investors seeking to identify dominant players and potential growth opportunities.

Market Overview

The global market share for steering knuckles is influenced by OEM production volumes, aftermarket demand, and the adoption of advanced lightweight materials. Manufacturers focusing on high-performance vehicles, electric vehicles (EVs), and luxury cars have been able to capture a significant share due to the demand for aluminum and forged steel components. Meanwhile, steel remains a staple in commercial vehicles and cost-sensitive passenger cars.

Market Segmentation by Material

Aluminum Steering Knuckles: Aluminum is lighter than steel, helping reduce vehicle weight and improve fuel efficiency. It is the preferred choice for EVs and premium vehicles.

Steel Steering Knuckles: Steel is strong, durable, and cost-effective, dominating the commercial vehicle segment and budget-friendly passenger cars.

Cast Iron Steering Knuckles: Still used in some heavy-duty applications due to its durability and cost-effectiveness, although its share is declining.

Vehicle Type Segmentation

Passenger Cars: The largest contributor to market share due to high global production volumes.

SUVs and Crossovers: Increasing popularity of SUVs drives demand for lightweight, durable steering knuckles.

Commercial Vehicles: Steel knuckles dominate this segment due to load-bearing requirements.

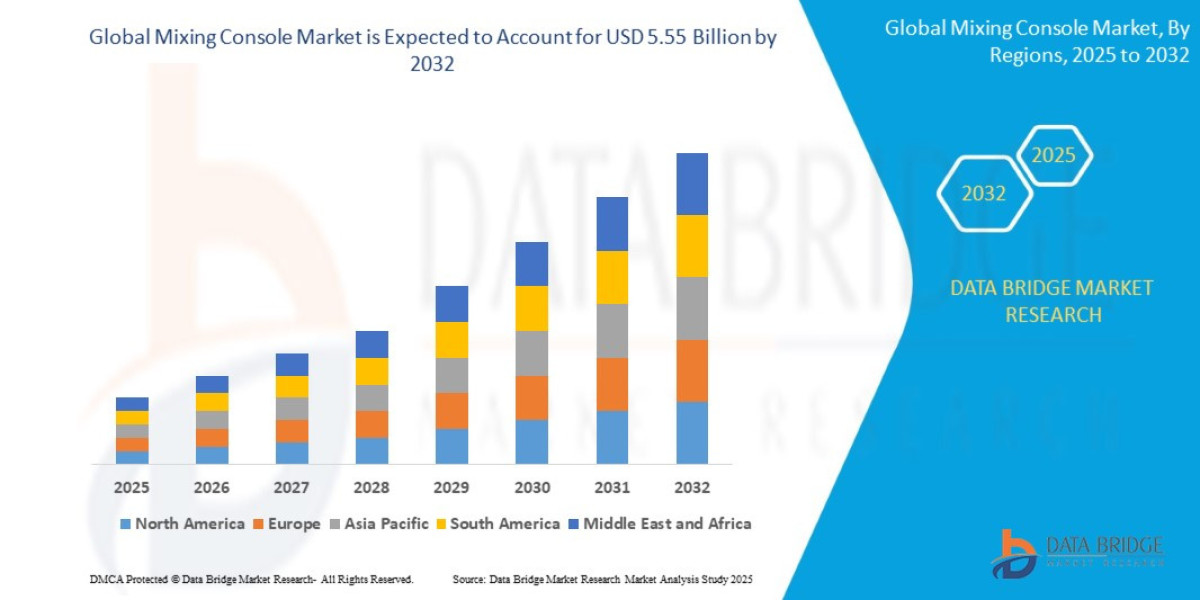

Regional Insights

Asia-Pacific: Leads in market share due to high vehicle production in China, India, and Japan.

North America: Premium vehicles and EV adoption give aluminum knuckles a larger revenue share.

Europe: Stricter safety regulations and growing EV adoption influence market share.

Growth Trends

OEM Dominance: OEMs contribute most of the market share, as automakers prefer long-term supplier relationships for quality and reliability.

Aftermarket Expansion: The growing trend of vehicle customization and replacement drives aftermarket market share, particularly in developed regions.

Strategic Alliances: Mergers and partnerships between global suppliers increase their combined market share, enabling them to capture more high-value segments.

Challenges

Intense competition from low-cost manufacturers

Material cost fluctuations affecting pricing

Complexity in integrating new materials with existing production systems

Future Outlook

The market share is expected to gradually shift toward lightweight aluminum and forged knuckles as EV adoption and premium vehicle production increase. Companies that focus on innovation, cost efficiency, and strategic partnerships are poised to capture a larger portion of the market in the coming decade.

FAQs

Which material holds the largest market share?

How is the market split between OEM and aftermarket?

Which region has the highest share of aluminum knuckles?

How do luxury and EV vehicles affect market share?

More Related Report

Telematics In Automotive Market Size