Introduction

Alkylation is a critical refining process that produces high-octane blending components for gasoline by combining light olefins (such as propylene and butylene) with isobutane in the presence of an acid catalyst. This process yields alkylate, a clean-burning, low-vapor-pressure component that improves engine performance and reduces emissions. With global efforts to improve fuel quality, stringent environmental regulations, and steady demand for higher-octane fuels, the alkylation market has become an important segment of the refining and petrochemical industries. This report provides a comprehensive view of the current market dynamics, segmentation, regional drivers, competitive landscape, and future opportunities for stakeholders.

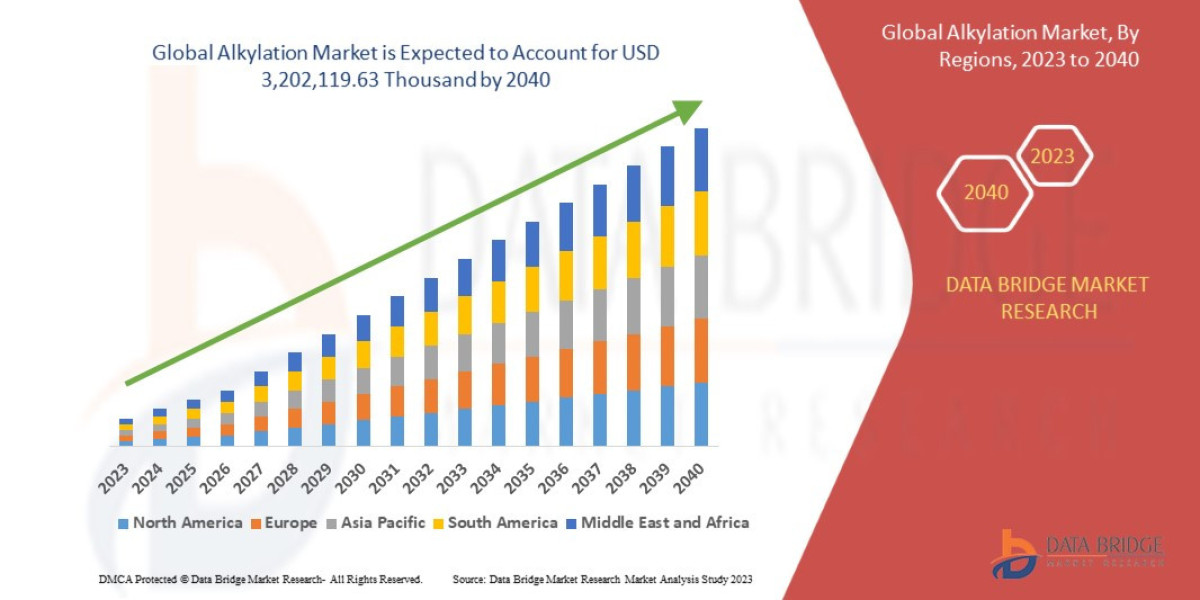

Review comprehensive data and projections in our Global Alkylation Market report. Download now: https://www.databridgemarketresearch.com/reports/global-alkylation-market

Market Overview

The global alkylation market is shaped by the twin needs of producing cleaner gasoline and maximizing refinery margins. Alkylate is prized because it delivers high octane without the undesirable aromatic content found in other octane-boosting streams. Key growth drivers include rising vehicle ownership in emerging markets, refinery modernization programs to meet stricter fuel specifications, and investment in capacity to replace older, environmentally problematic technologies.

Conversely, capital intensity, safety and environmental concerns (especially around hydrofluoric acid), feedstock volatility, and potential long-term declines in gasoline demand due to electrification present challenges. Still, opportunities exist in catalyst innovation (solid-acid catalysts), retrofit projects, integration with petrochemical value chains, and adoption of alternative feedstocks including bio-derived olefins.

Key Market Trends

Shift toward low-environmental-risk technologies: Historically, sulfuric acid (H₂SO₄) and hydrofluoric acid (HF) have dominated. Increasing regulatory and community pressure is accelerating interest in solid acid catalysts and safer process designs that lower the risk of hazardous releases and reduce acid consumption and waste handling costs.

Demand for high-octane, low-emission fuels: Regulations that require lower RVP (Reid Vapor Pressure) and cleaner fuel specifications sustain demand for alkylate as a blending component that meets both octane and emissions objectives.

Catalyst and process innovation: Advances in solid acids, ionic liquids, and improved process configurations aim to reduce operating expenses, improve selectivity, and simplify acid management. These technological developments are a major focus for suppliers and licensors.

Integration with petrochemical growth: As refineries seek flexibility, alkylation units are sometimes positioned to utilize byproduct olefins from petrochemical operations, improving overall plant economics.

Retrofits and revamps: Refineries in mature markets invest in revamps to replace HF units or to add alkylation capacity that supports higher gasoline quality and compliance with tightened local fuel standards.

Market Segmentation Analysis

By Catalyst Type

Sulfuric Acid (H₂SO₄): Widely used due to operational familiarity and proven performance. H₂SO₄ units require acid regeneration and handling infrastructure.

Hydrofluoric Acid (HF): Offers high octane and good olefin conversion efficiency, but safety concerns and community risk have reduced its favorability in some regions.

Solid Acid Catalysts & Alternative Technologies: Emerging segment focused on reducing environmental risk and operating complexity. Adoption is growing but remains constrained by scale-up and cost considerations.

Fastest-growing segment: Solid acid and alternative technologies are the fastest-growing due to safety and environmental drivers.

By Application

Fuel Production (Gasoline blending): Dominant application; alkylate improves octane and reduces undesirable aromatics.

Petrochemicals & Specialty Chemicals: Smaller but important applications where alkylation products can be feedstocks for downstream chemistries.

Fastest-growing application: Fuel production, driven by regulatory and quality requirements.

By End-Use Industry

Refining: Primary end user for alkylation units.

Automotive & Transportation: Indirect end-user through fuel demand.

Specialty Chemical Manufacturers: Niche consumers for certain alkylate fractions.

By Geography

Asia-Pacific: Largest growth market driven by rapid motorization, refinery expansions in China, India, and Southeast Asia, and ongoing investments to meet stricter fuel standards.

North America: Mature market with ongoing retrofits, environmental scrutiny, and strategic investments in safer technologies.

Europe: Strict emissions and environmental regulations push for cleaner fuels and safer alkylation alternatives.

Middle East & Africa: Investments in refinery and petrochemical capacity drive demand; many projects are expansionary but also cost-sensitive.

Latin America: Growing refining projects and upgrades support moderate demand growth.

Regional Analysis

North America: Availability of feedstock from petrochemical cash flows, advanced refinery infrastructure, and strong emphasis on community safety shape technology choices. Retrofits away from HF are particularly prominent.

Europe: Regulatory stringency favors low-emission solutions and incentivizes adoption of safer, less hazardous catalysts. Market growth is steady but constrained by lower gasoline growth forecasts.

Asia-Pacific: Rapid industrialization and growing vehicle fleets make Asia-Pacific the largest and fastest-growing regional market. Investments in new refinery capacity, combined with requirements for cleaner fuels, underline strong alkylation demand.

Latin America: Refinery modernization programs and new projects in countries with growing energy needs create near-term opportunities.

Middle East & Africa: Significant downstream investments and petrochemical integration present demand prospects, especially where governments are diversifying value chains.

Competitive Landscape

The alkylation market features a mix of major integrated oil & gas companies, licensors, technology providers, and engineering firms. Notable players include integrated refiners (who operate their own alkylation units) and technology licensors and engineering firms that provide process licenses, catalysts, and turn-key solutions. Market participants pursue strategies such as technology licensing, strategic partnerships, retrofits, and research into solid acid technology.

Key competitive dynamics:

Technology differentiation: Licensors offering safer, more efficient processes gain preference, particularly for retrofit projects.

Aftermarket services and catalyst supply: Long-term service contracts and catalyst performance assurances drive customer relationships.

Regional partnerships: Local EPCs and licensors collaborate with international tech owners to deliver projects tailored to local regulatory and feedstock conditions.

Future Outlook

The medium-term outlook for the alkylation market remains positive, driven by ongoing demand for high-octane gasoline blending components and the need for cleaner, more regulated fuels. Over the next 5–10 years, market growth will be influenced by:

Sustainability drivers: A stronger push towards solid-acid systems and safer alkylation technologies to mitigate environmental and safety risks.

Feedstock dynamics: Availability and pricing of light olefins and isobutane will affect operating margins and investment decisions.

Electrification of transport: Widespread EV adoption could moderate gasoline demand in mature markets; however, growth in emerging markets and the need to improve remaining gasoline quality will sustain demand for alkylation capacity.

Integration with renewables: Potential for bio-derived olefins as feedstock and integration with biofuels production could open new avenues.

Overall, while structural shifts in the global energy mix present uncertainty, demand for high-quality gasoline components and stricter fuel standards create a resilient base for alkylation services and technology investment.

Conclusion

Alkylation remains a cornerstone process in modern refining, delivering high-octane, low-emission blending components that help refiners meet regulatory and market requirements. While safety concerns and feedstock volatility present challenges, innovation in catalysts and process design, combined with strategic retrofits and capacity expansions—especially in Asia-Pacific—present meaningful opportunities for technology providers, refiners, and investors. Stakeholders who prioritize safety, operational efficiency, and flexibility to handle diverse feedstocks will be best positioned to capture value in the evolving alkylation market.

Frequently Asked Questions (FAQs)

Q1: What is alkylation and why is it important?

A: Alkylation is a refining process that combines light olefins with isobutane to produce alkylate, a high-octane, clean-burning gasoline blending component. It is important because alkylate improves fuel octane without raising aromatic or benzene content, helping refiners meet environmental regulations and consumer performance expectations.

Q2: Which catalyst types are used in alkylation?

A: The main catalyst types have historically been sulfuric acid (H₂SO₄) and hydrofluoric acid (HF). Emerging alternatives include solid acid catalysts, ionic liquids, and other novel chemistries that aim to reduce environmental risk and operating complexity.

Q3: Which region holds the largest market share?

A: While precise shares vary over time, Asia-Pacific currently represents the largest and fastest-growing region due to expanding refining capacity, rising vehicle fleets, and stricter fuel quality standards.

Q4: What are the primary drivers of market growth?

A: Key drivers include demand for higher-octane, low-emission gasoline blends; modernization and expansion of refinery capacity; and regulatory pressure to reduce emissions and improve fuel quality.

Q5: Who are the top players in the alkylation market?

A: The market comprises integrated refiners, technology licensors, and engineering firms. Leading licensors and technology providers partner with refiners to supply processes, catalysts, and turn-key solutions.

Q6: How will electric vehicles affect the alkylation market?

A: Electric vehicles may reduce gasoline demand growth in mature markets over the long term, but near- to medium-term demand for high-quality gasoline components remains due to ongoing use of internal combustion engines in many regions. Emerging markets’ growth and regulatory demands will temper the impact on alkylation capacity needs.

Browse More Reports:

Global Primary Clostridioides Difficile Infection Market

Global Processed Meat Speciation Testing Market

Global Process Mining Software Market

Global Proliferative Diabetic Retinopathy Market

Global Protein Assays Market

Global Proximity Cards Market

Global Psychedelic Mushroom Market

Global Pulse Fibres and Grits Market

Global Pulse Ingredients Market

Global Pyogenic Granuloma Treatment Market

Global Radio-frequency Identification (RFID) Blood Monitoring Systems Market

Global Railways Telematics Market

Global Rapid Prototyping Material Market

Global Ready-to-Use Pharmaceutical Packaging Market

Global Recreational Oxygen Equipment Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com